In April, we wrote about how there is a shortage of semiconductor chips (not edible ones) that is proving to be detrimental for various industries.

Well, the shortage still exists. Surprise!

In fact, it’s probably worse than before because more factors are at play- not just COVID.

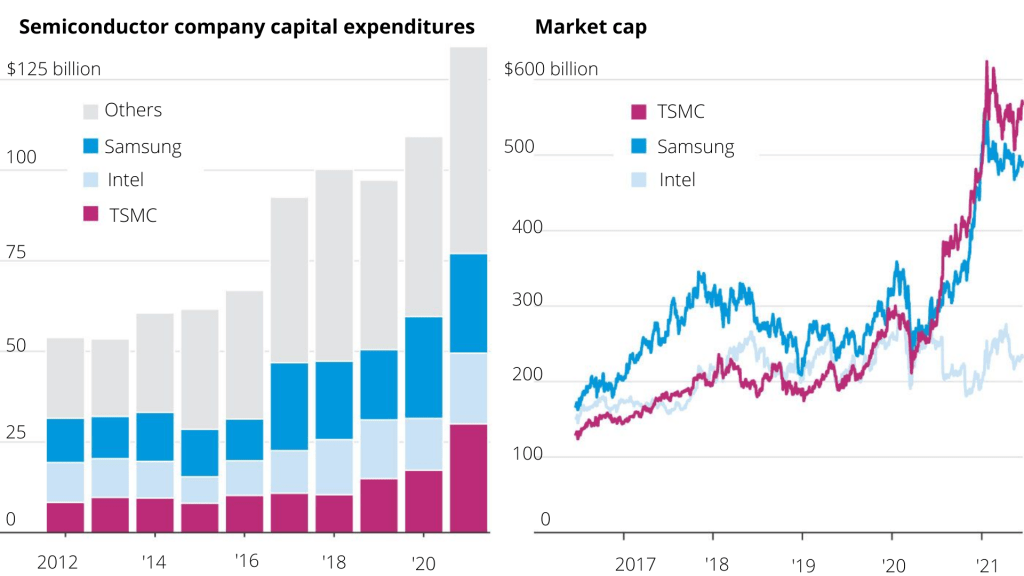

Semiconductor chips are like the heart and soul of computers, cars, smartphones, digital cameras, televisions, refrigerators etc. The pandemic induced the demand for chips as work from home became the new norm. Computer and smartphone manufacturers starting giving larger orders for chips. Automobile industry recovered from the pandemic faster than they anticipated and hence their demand also grew. All of this contributed to the chip manufacturers receiving orders much larger than the ones before pandemic. Taiwan Semiconductor Manufacturing Company (TSMC) is a prominent chip manufacturer in the world. Their net income increased 50% from the 2019 level. The semiconductor industry experienced a 10% year-over-year growth overall.

This surge in demand was sudden and unexpected. The manufacturers weren’t able to meet the requirement and production further slowed down by lockdowns and coronavirus restrictions.

Now, they’re facing a new problem… Climate change!

Taiwan is the hub for chip manufacturers. Companies in Taiwan generated around 65% of the global revenues for outsourced chip manufacturing in the first quarter of 2021. And TSMC alone generated 56% of the global revenues. The bottom line is, the entire world is dependent on Taiwan for chips.

They are facing their worst drought in about 50 years. Typhoons are an important source of water in Taiwan. However, there haven’t been any in the past year. Even the rainfall levels remain at a record low.

Producing semiconductors consumes a lot of water. A LOT. TSMC uses more than 150,000 tons of water per day. That’s approximately 80 standard swimming pools. They require this water to clean the metal at each step of production.

Taiwan is normally a place with plenty of rain, which is why chip factories set up operations in the country. However, due to climate change and people’s water use habits, water shortage hasn’t been uncommon in the past decade. The drought they’re facing this year is the most severe one, since 1964. Their total rainfall was only 78% of the average. So chip manufacturers, mainly TSMC, are in a competition with locals for water usage.

Estimates say that TSMC is going to spend $18-20 million on water trucks. Since they manufacture a large percentage of the world’s chips, the entire global supply has been affected. Climate activists have projected that both, typhoons and spring rainfall, are expected to reduce significantly due to climate change. This will make only make it tougher to produce chips in Taiwan.

A lesson for the semiconductor industry: reduce geographical concentration

The world is dependent on Taiwan for their chip needs. TSMC in specific. This has proved to be detrimental for various industries as it created too much pressure on them and they weren’t equipped to meet such a large demand. Further, they’re dealing with a deadly wave of Covid and climate change – which isn’t helping their production. Which is why semiconductor industry needs to expand it’s operations beyond Taiwan, Singapore etc.

They also need to move away from concentrated competition as TSMC and Samsung have the largest market share. TSMC makes 92% of the world’s most sophisticated chips and Samsung makes the rest. TSMC also make 60% of the less-sophisticated microcontrollers that car makers need.

This shortage will change the industry as we know it. Buyers will place orders for chips with more than one producer and manufactures will expand their operations.

Companies have already started building new plants in US. Intel plans to spend $20 billion on two new plants in Arizona. The construction of a $12 billion TSMC factory has already begun in Arizona. Further, Joe Biden included $50 billion dollars for the semiconductor in America in his $2 trillion infrastructure investment package. This will fund construction of new plants (which usually cost $10 billion or more), and expansion of existing plants.

It will take many months before the factory is completely built and up and running. No one is sure how long the chip shortage will persist. But all the predictions have one thing in common- it’s not going to be solved soon. It’s going to take its time.

Automobile industry is just one of the few that has been hit because of this. Ford estimates that they’ll lose out on sales worth $2.5 billion. While General Motors expects their the shortage to cut their earnings by $1.5 billion to $2 billion. The waiting periods for cars have crossed the one year mark!

The consequences can be felt in India as well, because of the long waiting periods for cars. The waiting period for Hyundai Creta is 9 months) followed closely by Maruti Ertiga (8 months). These are just a few of the many cars with a longgg waiting period.

The chip shortage is worse than anyone initially estimated or expected. We can only patiently wait for more chip factories to come up and hope Taiwan’s coronavirus and drought situation gets better!

Leave a reply to K-power: Hallyu’s influence – The Echo-nomist Cancel reply